So early this spring I started hearing a rolling-rattling noise which did not correlate to speed or throttle but did correlate to engine/drive train load. Noise would occur when accelerating uphill from 20mph but not cruising at 40mph on level road; and noise would occur when cruising on level road at 55+mph but not going downhill at 60mph. As a note, this bike is fully stock with 24k miles.

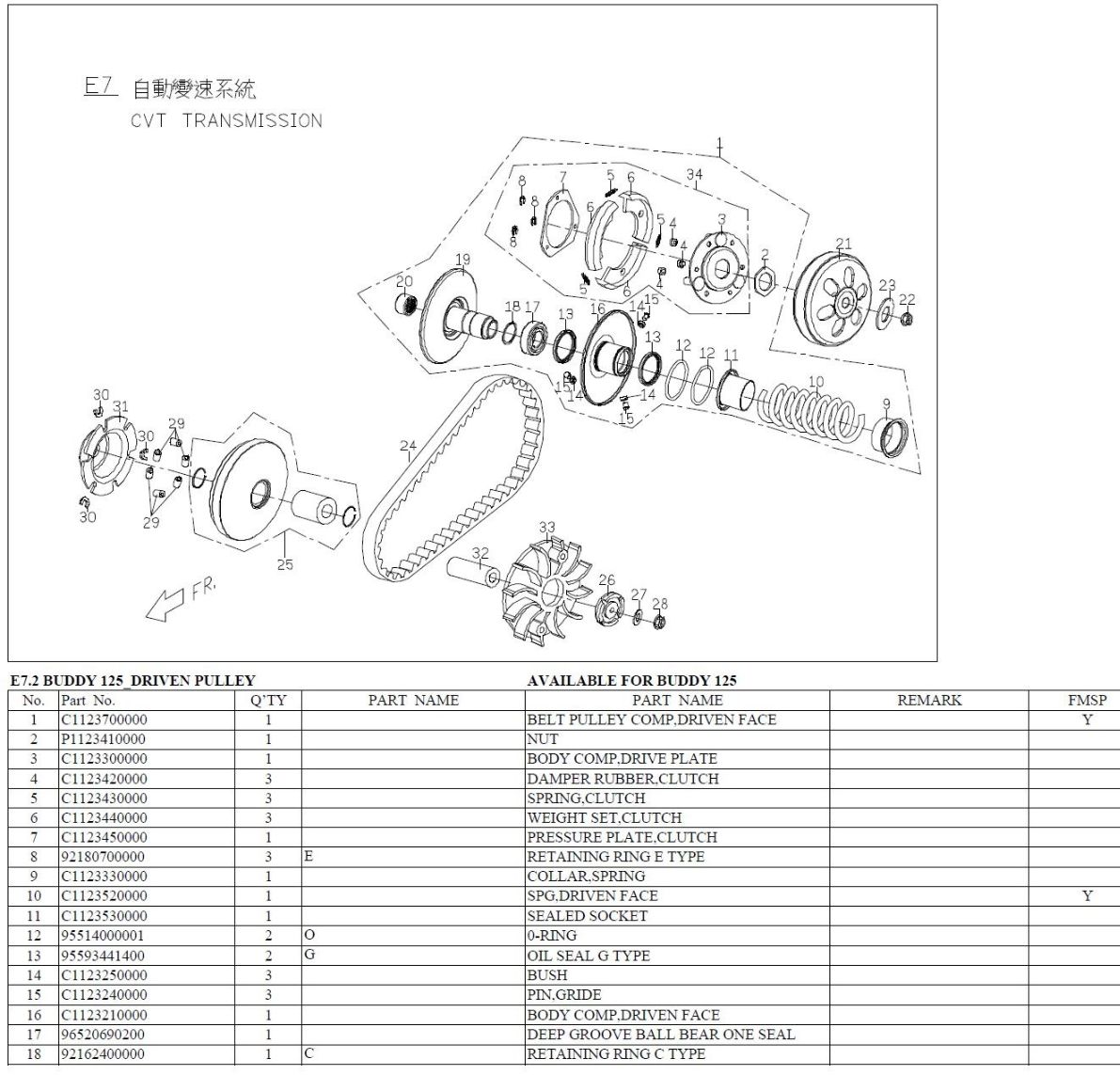

I eventually determined it to be the driven belt pulley bearings going dry. I don't know if it was the ball bearings or the needle bearings because I repacked both with grease and the noise went away. Of course it wasn't that fast or simple -- I did many maintenance & test run evolutions and luckily got it fixed the night before a group ride I wanted to do.

First I thought it was going to be the drive belt, which I found to be at the spec end-of-service-life, or the boss in driving belt pulley assembly. Don't get me started on how that Gates belt from ScooterWorks was never the width it should have been and thus I got only about half the life I get from PGO Bando belts my shop sells (yeah, my shop is ~75 miles away so I went the online route last year). Adding a touch of oil to the gear box didn't fix things either, but did cause oil to weep from it (i.e. something to clean up).

Once belt was replaced and pulley checked & cleaned and checked & cleaned, I wondered about engine bearings or timing chain & tensioner (even though I didn't hear chain slap at idle). Chain looked good when I lashed the valves and replaced my aging spark plug. My supportive shop (shout-out for Scoot Richmond) said bearings should last life of engine, but at 24k I may be getting near that. Even though I always keep good oil at proper level, am getting same great mpg, top speed & pull still good, and hear 30k-40k miles life is very achievable, this had me worried -- I love riding my Buddy 150 and it's grocery hauling capacity.

Out of desperation I replace my sliders with some lighter ones I didn't really like but kept just-in-case. Still that damned noise persisted so back in go my old sliders. I cannot believe the variator would wear from sliders.

Then I searched MB for "bearing AND noise" and found this thread (even though I was really thinking engine bearings). Reading of others' issues with dead driven pulley bearings jogged my brain. I remembered that I had wondered about how much grease should be on those bearings when doing general clean-up & inspection as part of my belt replacement several weeks before.

I didn't take the driven pulley apart, I just used a bamboo skewer to reach through the assembly and place grease on the ball bearings. Then I used a Q-tip to get it pushed down and smeared around better while removing excess. For the needle bearings I just used the skewer to smear grease on them and kind of roll them around. Yep, did it all without duct tape

Anyway, thanks for keeping these old posts around -- they are still helpful.