horn button

Moderator: Modern Buddy Staff

- JoshWED

- Member

- Posts: 188

- Joined: Wed Jun 09, 2010 1:43 pm

- Location: District of Columbia

horn button

anyone ever moved the button for the horn? i know many have moved the actual horn, but I'm talking about the button you push to sound it.

i find it difficult to be ready to give a quick honk to warn cagers, pedestrians of my presence when i'm also working with the clutch.

(of course i realize the best way to react to emergent situations is to have your escape route planned and be ready to act on it. so i guess what i'm really saying is, "wouldn't it be nice to be able to lay on your horn after you've escaped to a safe lane but are still engaging the clutch to, you know, drive?")

i find it difficult to be ready to give a quick honk to warn cagers, pedestrians of my presence when i'm also working with the clutch.

(of course i realize the best way to react to emergent situations is to have your escape route planned and be ready to act on it. so i guess what i'm really saying is, "wouldn't it be nice to be able to lay on your horn after you've escaped to a safe lane but are still engaging the clutch to, you know, drive?")

- Halloweenie

- Member

- Posts: 147

- Joined: Mon Nov 03, 2008 7:40 pm

- Location: Drexel Hill, PA

I know there was one person on stellaspeed that created a foot pedal for a horn. However, I think that was for an air horn they added to their bike.

I will say that I thought the same thing when I first started riding, but after a year I have no problem finding it in a pinch. I just wish it had more umph.

I will say that I thought the same thing when I first started riding, but after a year I have no problem finding it in a pinch. I just wish it had more umph.

226 Vintage Hot Wing, GGR Hot Reeds, Mazzy Race Cut Crank, P200 filter, 128 Main, BJ Stack, Trailtech CHT

AAA-O Anything, Anytime, Anywhere, Bar None

AAA-O Anything, Anytime, Anywhere, Bar None

- JoshWED

- Member

- Posts: 188

- Joined: Wed Jun 09, 2010 1:43 pm

- Location: District of Columbia

- Halloweenie

- Member

- Posts: 147

- Joined: Mon Nov 03, 2008 7:40 pm

- Location: Drexel Hill, PA

-

lilmyk

- Member

- Posts: 10

- Joined: Mon Mar 16, 2009 8:39 pm

- Location: Greensboro NC

- polianarchy

- Moderator

- Posts: 2163

- Joined: Mon Dec 04, 2006 6:16 pm

- Location: SJCA

- Contact:

- Silver Streak

- Member

- Posts: 481

- Joined: Wed Mar 17, 2010 3:42 pm

- Location: Annapolis, MD

It would work, but you'd have to turn it back off to end your "toot."polianarchy wrote:I wonder if I can use my disabled kill switch for an air horn? Hmm! Anyone done this mod?

Horn switches are normally spring-loaded, momentary contact switches, which a kill switch is not (it has an "on and an "off" detent, with no spring return).

Also, any time you "repurpose" a switch for an air horn, you need to take into account the current draw of the horn and the switch's contact rating. For something robust like a Stebel Nautilus, you really need to wire the switch through a relay to take the current load off the switch.

Dave

www.glyphukulele.com

"You do not need a parachute to skydive. You only need a parachute to skydive twice."

www.glyphukulele.com

"You do not need a parachute to skydive. You only need a parachute to skydive twice."

- jmkjr72

- Member

- Posts: 783

- Joined: Sat Jul 11, 2009 11:07 pm

- Location: green bay wi

- Contact:

no she wouldnt the stella does not use a kill switch it uses a kill buttonSilver Streak wrote:It would work, but you'd have to turn it back off to end your "toot."polianarchy wrote:I wonder if I can use my disabled kill switch for an air horn? Hmm! Anyone done this mod?

Horn switches are normally spring-loaded, momentary contact switches, which a kill switch is not (it has an "on and an "off" detent, with no spring return).

a momentary switch

- jmkjr72

- Member

- Posts: 783

- Joined: Sat Jul 11, 2009 11:07 pm

- Location: green bay wi

- Contact:

as long as disable the part that wont let you engage your starter when the scooter is runninglilmyk wrote:I removed my starter, which frees up the Start Button.

I am adding an Air Horn and will be using the Starter Button for it.

You can use the starter relay in place of the air horn relay.

And I am actually working on a bracket to mount the air horn compressor where the starter was.

- Halloweenie

- Member

- Posts: 147

- Joined: Mon Nov 03, 2008 7:40 pm

- Location: Drexel Hill, PA

-

lilmyk

- Member

- Posts: 10

- Joined: Mon Mar 16, 2009 8:39 pm

- Location: Greensboro NC

I am full DC on my scoot, upgraded some bulbs to LED and will add HID when I get some more money.Halloweenie wrote:Hell, if you are going to kill the starter you might as well go full DC and install a HID system.

I have another Stella that I can't get spark out of that I need to get running and unload first.

- Silver Streak

- Member

- Posts: 481

- Joined: Wed Mar 17, 2010 3:42 pm

- Location: Annapolis, MD

Thanks for the correction. I'm still waiting for my 4T Stella, so I was going by other scoots I've owned. Actually, I think a momentary button is probably superior, as it can't be left in the "off" position inadvertently.jmkjr72 wrote:no she wouldnt the stella does not use a kill switch it uses a kill buttonSilver Streak wrote:It would work, but you'd have to turn it back off to end your "toot."polianarchy wrote:I wonder if I can use my disabled kill switch for an air horn? Hmm! Anyone done this mod?

Horn switches are normally spring-loaded, momentary contact switches, which a kill switch is not (it has an "on and an "off" detent, with no spring return).

a momentary switch

Dave

www.glyphukulele.com

"You do not need a parachute to skydive. You only need a parachute to skydive twice."

www.glyphukulele.com

"You do not need a parachute to skydive. You only need a parachute to skydive twice."

- Halloweenie

- Member

- Posts: 147

- Joined: Mon Nov 03, 2008 7:40 pm

- Location: Drexel Hill, PA

I would not trust the thing, chances are you'd end up with the horn on all the time after a good rainfall. Everyone I know with a Stella has the stupid thing disconnected as is, just for the piece of mind.polianarchy wrote:I wonder if I can use my disabled kill switch for an air horn? Hmm! Anyone done this mod?

226 Vintage Hot Wing, GGR Hot Reeds, Mazzy Race Cut Crank, P200 filter, 128 Main, BJ Stack, Trailtech CHT

AAA-O Anything, Anytime, Anywhere, Bar None

AAA-O Anything, Anytime, Anywhere, Bar None

- polianarchy

- Moderator

- Posts: 2163

- Joined: Mon Dec 04, 2006 6:16 pm

- Location: SJCA

- Contact:

Yeah, that's why we disabled the starter right when I bought it. Too many '08s had wonky kill switches/buttons/whatevers. Eh, I'll probably just end up leaving the horn alone unless someone else comes up with a better idea.Halloweenie wrote:I would not trust the thing, chances are you'd end up with the horn on all the time after a good rainfall. Everyone I know with a Stella has the stupid thing disconnected as is, just for the piece of mind.polianarchy wrote:I wonder if I can use my disabled kill switch for an air horn? Hmm! Anyone done this mod?

ModBud #442

- JoshWED

- Member

- Posts: 188

- Joined: Wed Jun 09, 2010 1:43 pm

- Location: District of Columbia

- PeterC

- Member

- Posts: 517

- Joined: Fri Aug 22, 2008 11:04 pm

- Location: Green Valley, AZ

- Halloweenie

- Member

- Posts: 147

- Joined: Mon Nov 03, 2008 7:40 pm

- Location: Drexel Hill, PA

Sure is, you are one of the two people that have done it to my knowledge. I really liked the idea, but I just cannot bring myself to go mucking about with the wiring, a wee bit too scary.Was this the one you referred to?

226 Vintage Hot Wing, GGR Hot Reeds, Mazzy Race Cut Crank, P200 filter, 128 Main, BJ Stack, Trailtech CHT

AAA-O Anything, Anytime, Anywhere, Bar None

AAA-O Anything, Anytime, Anywhere, Bar None

- PeterC

- Member

- Posts: 517

- Joined: Fri Aug 22, 2008 11:04 pm

- Location: Green Valley, AZ

The wiring is really extraneous to the existing Stella/P200 wiring. It involves a Stebel Nautilus air horn, which I mounted on the rear rack, a standard auto supply store horn button, an in-line fuse and the relay which is supplied with the Stebel horn. If the electrical diagrams seem confusing, bring the project in to your local auto garage, and any competent mechanic can hook it up for you. The mechanical mounting of the horn and relay is easy, and the only complication with the horn button is insulating it from the scooter floorboard (use a thin piece of rubber, cut to fit), so it doesn't short out.Halloweenie wrote:Sure is, you are one of the two people that have done it to my knowledge. I really liked the idea, but I just cannot bring myself to go mucking about with the wiring, a wee bit too scary.Was this the one you referred to?

- ericalm

- Site Admin

- Posts: 16842

- Joined: Sat Jun 10, 2006 3:01 am

- Location: Los Angeles, CA

- Contact:

What odd placement for that Stebel!

The 4T kill switch works fine, though not like other scooters. You really have to hold it for a second.

Unlike an auto scooter, though, there's a good chance your scooter will stall and not be running on its side in a crash. I think.

The horn/kill switch mod is a good idea. I'll have to think about that one. As is, I just don't use my horn like I do on the Vespa.

I'm a bit worried about confusion while riding. Twice I've hit the kill switch on the Vespa because it's where the turn signals are on the Stella! Oops.

The 4T kill switch works fine, though not like other scooters. You really have to hold it for a second.

Unlike an auto scooter, though, there's a good chance your scooter will stall and not be running on its side in a crash. I think.

The horn/kill switch mod is a good idea. I'll have to think about that one. As is, I just don't use my horn like I do on the Vespa.

I'm a bit worried about confusion while riding. Twice I've hit the kill switch on the Vespa because it's where the turn signals are on the Stella! Oops.

Eric // LA Scooter Meetup Group // Stella 4T // Vespa LX // Vespa LXS // Honda Helix // some, uh, projects…

- JoshWED

- Member

- Posts: 188

- Joined: Wed Jun 09, 2010 1:43 pm

- Location: District of Columbia

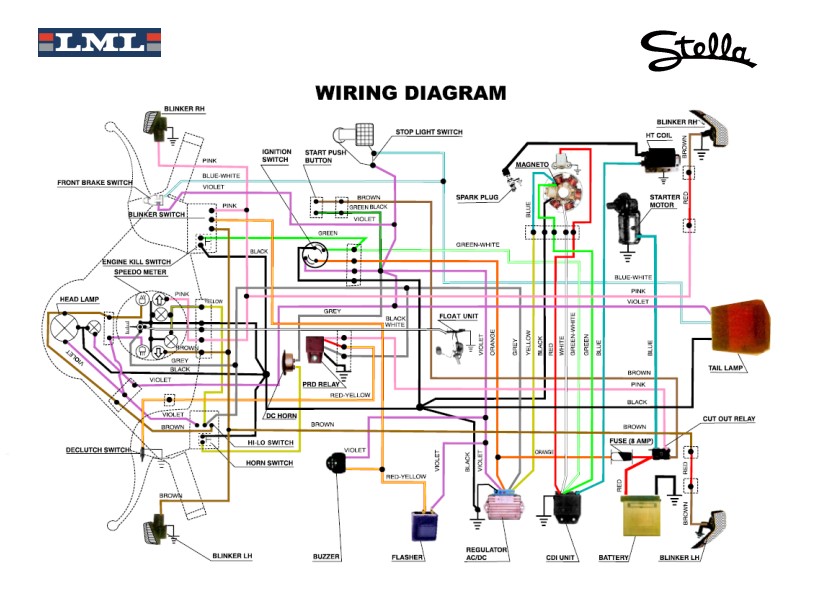

@eric. the kill switch on the 2T's is the same....you have to hold them down to kill the engine. this diagram should help explain why:

http://www.vespamaintenance.com/elec/cdiwork/

http://www.vespamaintenance.com/elec/cdiwork/

- Halloweenie

- Member

- Posts: 147

- Joined: Mon Nov 03, 2008 7:40 pm

- Location: Drexel Hill, PA

- PeterC

- Member

- Posts: 517

- Joined: Fri Aug 22, 2008 11:04 pm

- Location: Green Valley, AZ

- ericalm

- Site Admin

- Posts: 16842

- Joined: Sat Jun 10, 2006 3:01 am

- Location: Los Angeles, CA

- Contact:

I've seen an '80s Honda Elite 250 with twin air horns mounted on the body on the bottom of the legshield (sort of). It's like a freakin' truck!PeterC wrote:Eric, that would indeed be an odd placement for a Stebel, but not here in the Sonora Desert! It rarely rains around here, plus the Stebel is loud enough so it could be mounted anywhere and still be heard.ericalm wrote:What odd placement for that Stebel!:)

Eric // LA Scooter Meetup Group // Stella 4T // Vespa LX // Vespa LXS // Honda Helix // some, uh, projects…

- polianarchy

- Moderator

- Posts: 2163

- Joined: Mon Dec 04, 2006 6:16 pm

- Location: SJCA

- Contact:

- jmkjr72

- Member

- Posts: 783

- Joined: Sat Jul 11, 2009 11:07 pm

- Location: green bay wi

- Contact:

that is kinda simular to the way my xs1100 is set upericalm wrote: I've seen an '80s Honda Elite 250 with twin air horns mounted on the body on the bottom of the legshield (sort of). It's like a freakin' truck!

on the front fearing below the headlight i have dual air horns and the compressos is in the feraing and yes it is as loud as a truck but i would live to find a way to get a big enough compressor and tank on there to power a train horn

- loodieboy

- Member

- Posts: 331

- Joined: Tue Aug 05, 2008 8:48 pm

- Location: Ft. Thomas, KY

Okay, here is my plan. I have to disassemble both bars to cure the obnoxious rattle anyway, so while I am at it, I am going to disconnect the kill switch, cap the leads, then reroute the horn button wires to the kill switch. I hope to pull the existing horn button and cap the hole with a plug from Lowes. This will be a couple weekends away (painting the front porch, but I will report back on the results.

EDIT: Nevermind, playing make-believe on my commute, I find that the kill switch location is no more convenient than the existing horn button location. It's too far from the front brake lever.

EDIT: Nevermind, playing make-believe on my commute, I find that the kill switch location is no more convenient than the existing horn button location. It's too far from the front brake lever.

Clearly.

- JoshWED

- Member

- Posts: 188

- Joined: Wed Jun 09, 2010 1:43 pm

- Location: District of Columbia

So here's what I'm thinking: both the horn switch and the kill switch are both on black here:Silver Streak wrote:It would work, but you'd have to turn it back off to end your "toot."polianarchy wrote:I wonder if I can use my disabled kill switch for an air horn? Hmm! Anyone done this mod?

Horn switches are normally spring-loaded, momentary contact switches, which a kill switch is not (it has an "on and an "off" detent, with no spring return).

Also, any time you "repurpose" a switch for an air horn, you need to take into account the current draw of the horn and the switch's contact rating. For something robust like a Stebel Nautilus, you really need to wire the switch through a relay to take the current load off the switch.

Wouldn't it be simple enough to go to the root splice and switch the two? The kill switch would be the old horn button: useful because we're not fiddling with the clutch when we are switching off.

And of course, the kill switch would be the horn.

Am I missing something?

- JoshWED

- Member

- Posts: 188

- Joined: Wed Jun 09, 2010 1:43 pm

- Location: District of Columbia

Finally got around to this

Finally moved the horn button out of the twist-shift handle. Advantages of this mod: fewer wires coming through the twist-shift mechanism, so less wear on each wire, and; no shorting out of the horn wires (and attendant honk) every time I shift into first gear.

Method:

1. Remove the button plate on the left handle bar. Disconnect the horn wires (yellow and black).

2. Remove the horn plate. Locate the horn (round speaker near bottom). Find the yellow lead, and pull this lead through. It will slide easily out of the headset/handlebar.

3. The black lead is more difficult, as this lead doesn't go directly to the horn. Instead of trying to find where it splits from the gray DC line (that you see connected to the horn unit), you will find it easier to add more lead to the black wire in the headset. I used equally gauged automotive wire to do this...just capped and taped the connection and left the connection in the headset.

4. Snake the yellow and black leads into the glove box. There is a small hole near the top of the glove box where the wires for the turn signals come through. I used the hole for the left turn signal. To make snaking easy, I tied some butcher's twine to a paper clip. Working from inside the glove box, I then poked the paperclip through the turn-signal hole and out towards the front of the scooter. Once the butcher's twine was snaked, I simply wrapped the exposed copper leads into the twine and pulled back in the other direction.

5. Add a little more lead to the the yellow wire, with a junction in the glove box. This gives you a little more wire to work with. It also serves as an easy way to break the circuit in the case of the foot pedal shorting (which I could see happening during a heavy rainfall).

6. Snake the two leads out of the bottom of the glove box. There is a gap between the leg shield and the glove box that easily allows this.

7. Connect to the foot pedal and mount. I used a Sea Dog Marine Surface Mounted Push Button. I mounted below the glove box to afford some protection to the elements.

Method:

1. Remove the button plate on the left handle bar. Disconnect the horn wires (yellow and black).

2. Remove the horn plate. Locate the horn (round speaker near bottom). Find the yellow lead, and pull this lead through. It will slide easily out of the headset/handlebar.

3. The black lead is more difficult, as this lead doesn't go directly to the horn. Instead of trying to find where it splits from the gray DC line (that you see connected to the horn unit), you will find it easier to add more lead to the black wire in the headset. I used equally gauged automotive wire to do this...just capped and taped the connection and left the connection in the headset.

4. Snake the yellow and black leads into the glove box. There is a small hole near the top of the glove box where the wires for the turn signals come through. I used the hole for the left turn signal. To make snaking easy, I tied some butcher's twine to a paper clip. Working from inside the glove box, I then poked the paperclip through the turn-signal hole and out towards the front of the scooter. Once the butcher's twine was snaked, I simply wrapped the exposed copper leads into the twine and pulled back in the other direction.

5. Add a little more lead to the the yellow wire, with a junction in the glove box. This gives you a little more wire to work with. It also serves as an easy way to break the circuit in the case of the foot pedal shorting (which I could see happening during a heavy rainfall).

6. Snake the two leads out of the bottom of the glove box. There is a gap between the leg shield and the glove box that easily allows this.

7. Connect to the foot pedal and mount. I used a Sea Dog Marine Surface Mounted Push Button. I mounted below the glove box to afford some protection to the elements.

- Attachments

-

- Picture of pedal

- IMG_4935.JPG (164.42 KiB) Viewed 3959 times

- RoaringTodd

- Member

- Posts: 690

- Joined: Mon Jul 23, 2012 3:45 pm

- Location: Philly, PA

- jimmbomb

- Member

- Posts: 801

- Joined: Fri May 20, 2011 1:00 am

- Location: St Louis

Re: Finally got around to this

JoshWED wrote:Finally moved the horn button out of the twist-shift handle. Advantages of this mod: fewer wires coming through the twist-shift mechanism, so less wear on each wire, and; no shorting out of the horn wires (and attendant honk) every time I shift into first gear.

Method:

1. Remove the button plate on the left handle bar. Disconnect the horn wires (yellow and black).

2. Remove the horn plate. Locate the horn (round speaker near bottom). Find the yellow lead, and pull this lead through. It will slide easily out of the headset/handlebar.

3. The black lead is more difficult, as this lead doesn't go directly to the horn. Instead of trying to find where it splits from the gray DC line (that you see connected to the horn unit), you will find it easier to add more lead to the black wire in the headset. I used equally gauged automotive wire to do this...just capped and taped the connection and left the connection in the headset.

4. Snake the yellow and black leads into the glove box. There is a small hole near the top of the glove box where the wires for the turn signals come through. I used the hole for the left turn signal. To make snaking easy, I tied some butcher's twine to a paper clip. Working from inside the glove box, I then poked the paperclip through the turn-signal hole and out towards the front of the scooter. Once the butcher's twine was snaked, I simply wrapped the exposed copper leads into the twine and pulled back in the other direction.

5. Add a little more lead to the the yellow wire, with a junction in the glove box. This gives you a little more wire to work with. It also serves as an easy way to break the circuit in the case of the foot pedal shorting (which I could see happening during a heavy rainfall).

6. Snake the two leads out of the bottom of the glove box. There is a gap between the leg shield and the glove box that easily allows this.

7. Connect to the foot pedal and mount. I used a Sea Dog Marine Surface Mounted Push Button. I mounted below the glove box to afford some protection to the elements.

Nice!!! and thanks for the instruction!!!

Customize your ride!!!!

[/URL]

[/URL]